URQC-100

Ultrasonic Robotic Quality Control

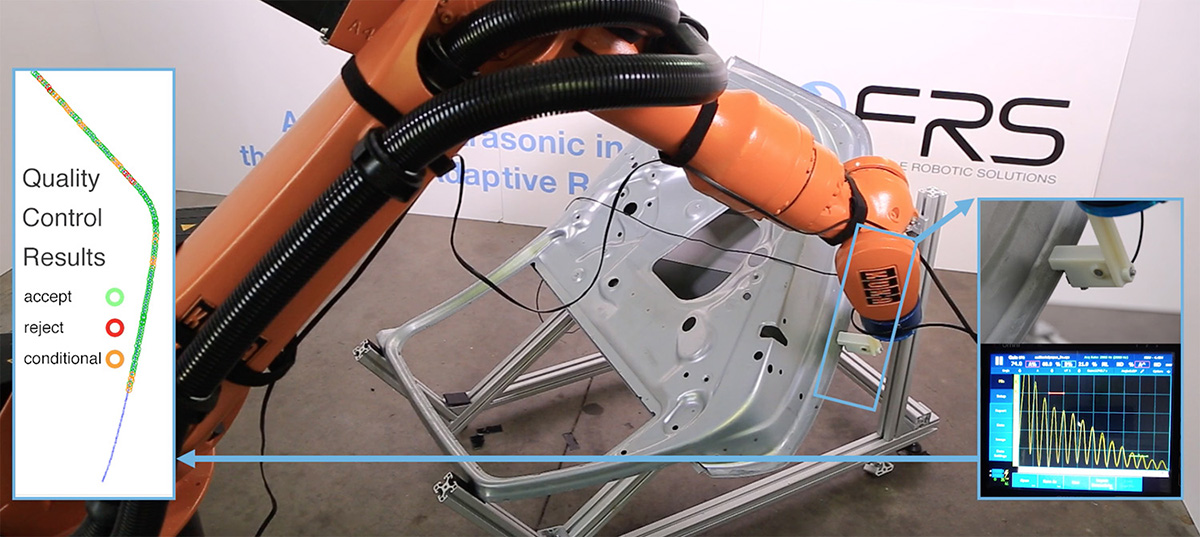

of Fold Glue Joints by an industrial robot

Solution under Development

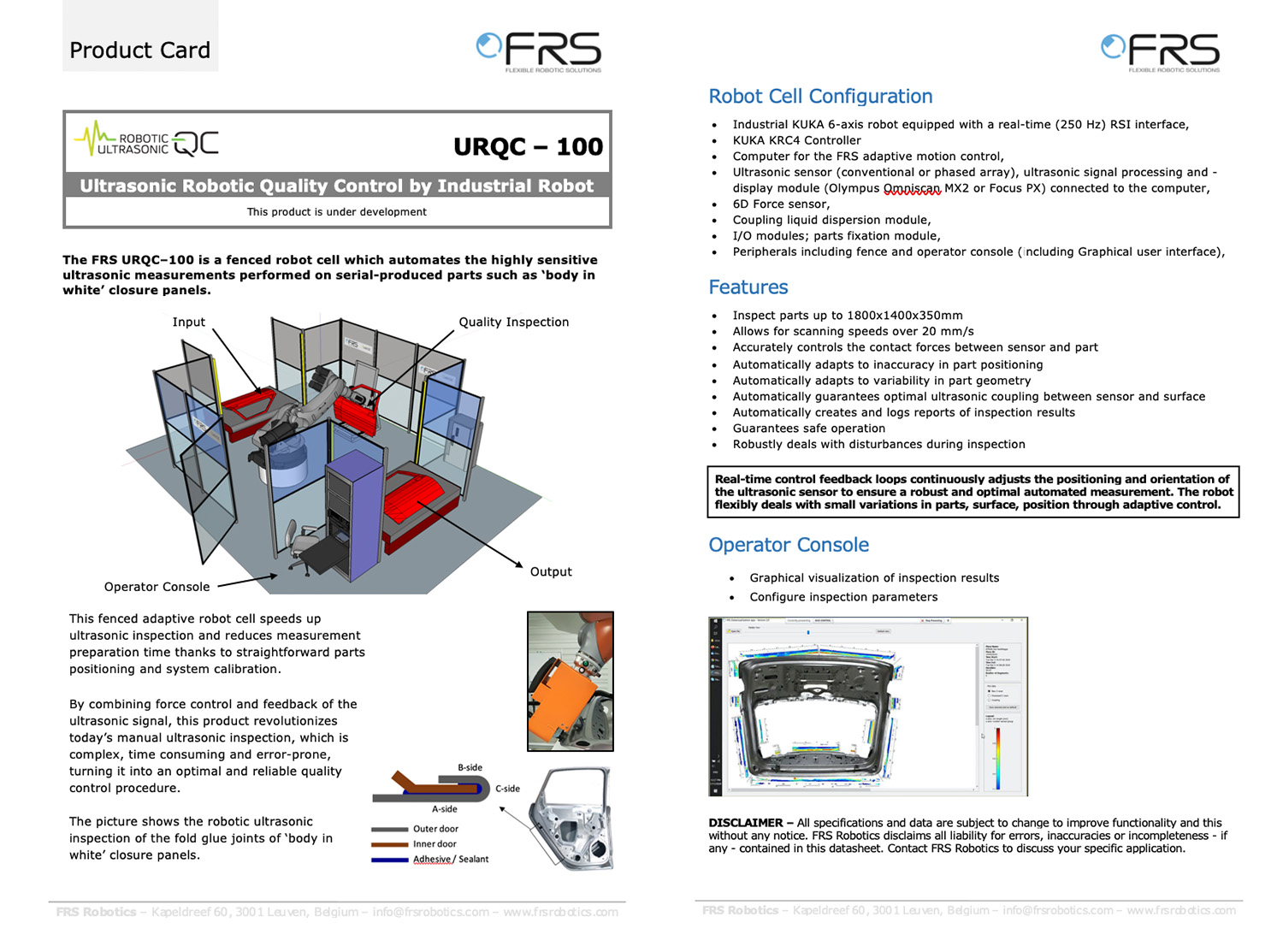

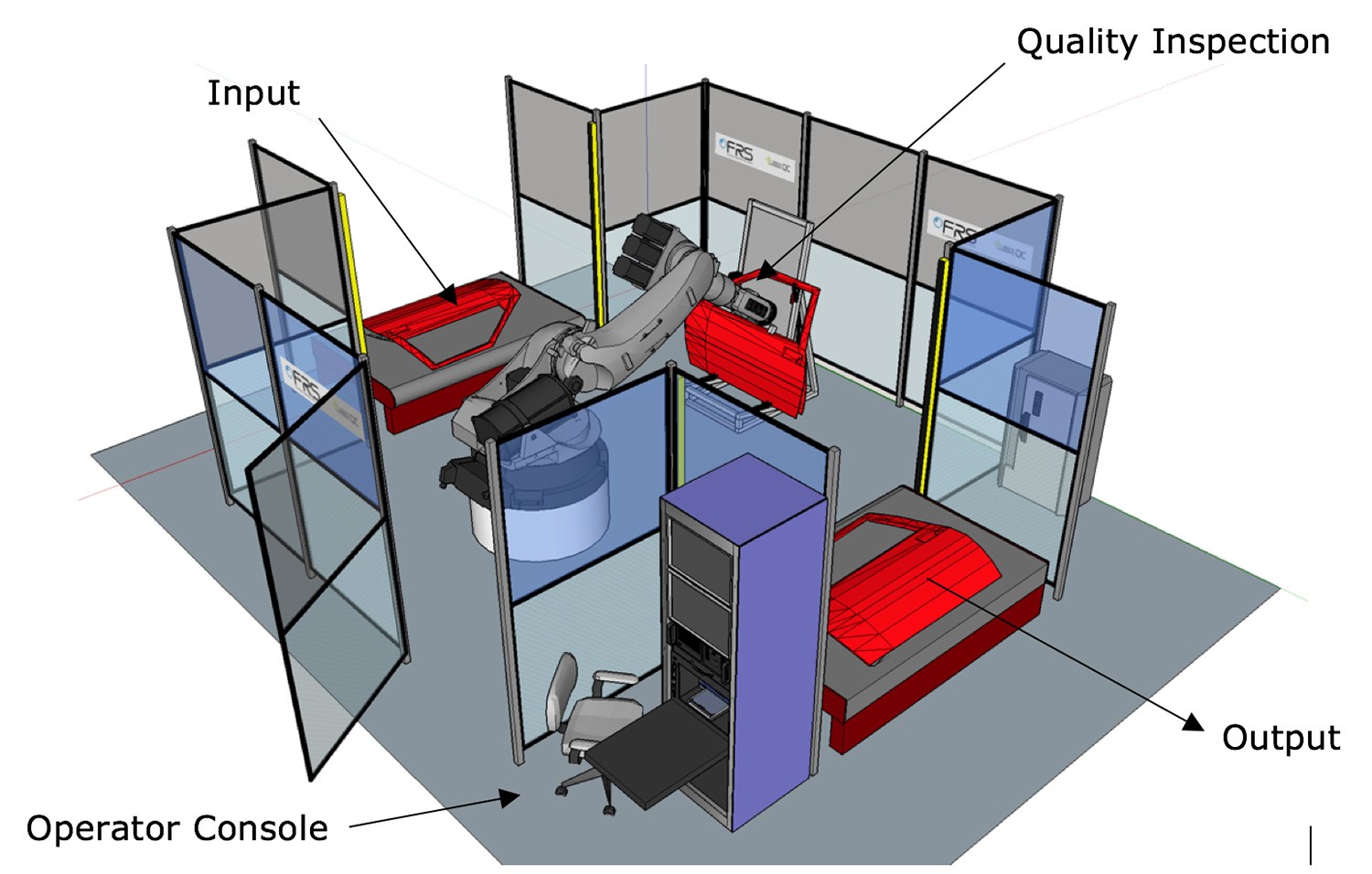

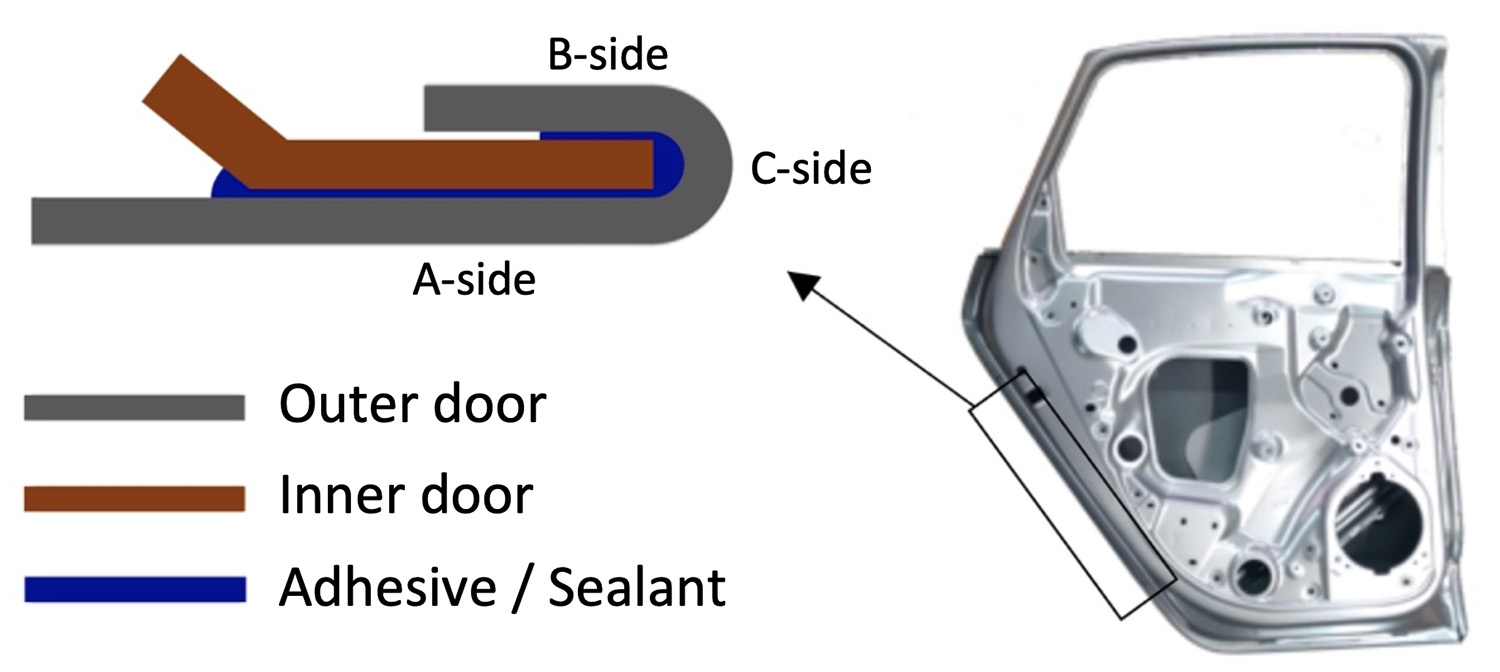

The FRS URQC-100 is a fenced robot cell which automates the highly sensitive ultrasonic quality measurements of fold glue joints of automotive closure panels. Because of operator absence, the inspection speed of the URQC-100 is higher than the URQC-200, while still ensuring optimal and reliable ultrasonic inspections. This fenced robot cell automates the highly sensitive ultrasonic quality measurements of fold glue joints on car body parts, such as doors, hood and trunk.

This product revolutionizes today’s complex manual ultrasonic quality control, which is time consuming and error prone. The FRS URQC-100 robot cell is suited for off-line, near-line and by-pass ultrasonic quality control. Complete in-line solutions are not possible due to the ultrasonic equipment which is unable to measure fast enough to comply with the fast cycle times. The automated ultrasonic inspection increases quality control reliability and speed and it significantly lowers the need for destructive testing, thus reducing material scrap (> 80% compared to destructive testing).

Automated, Robust, Fast & Flexible

In the past it has been difficult to robotically position an ultrasonic probe to measure a fold glue joint, because of small variances in the best position to get the optimal ultrasound signal. FRS has made this possible.

Automating highly sensitive ultrasonic inspection is made possible by introducing an innovative robot control feedback loop. Based on both the contact force and the ultrasonic signal, the patented feedback loop of FRS Robotics enables to continuously adjust sensor position and orientation in order to ensure valid measurements. The adaptive control guides the robot along the part edge while robustly acquiring valid ultrasonic measurement data.

- Automating complex manual ultrasonic quality control in a production environment

- Robustly handling geometric variations of the product

- Flexibly switching between item variants by clicking a few software buttons

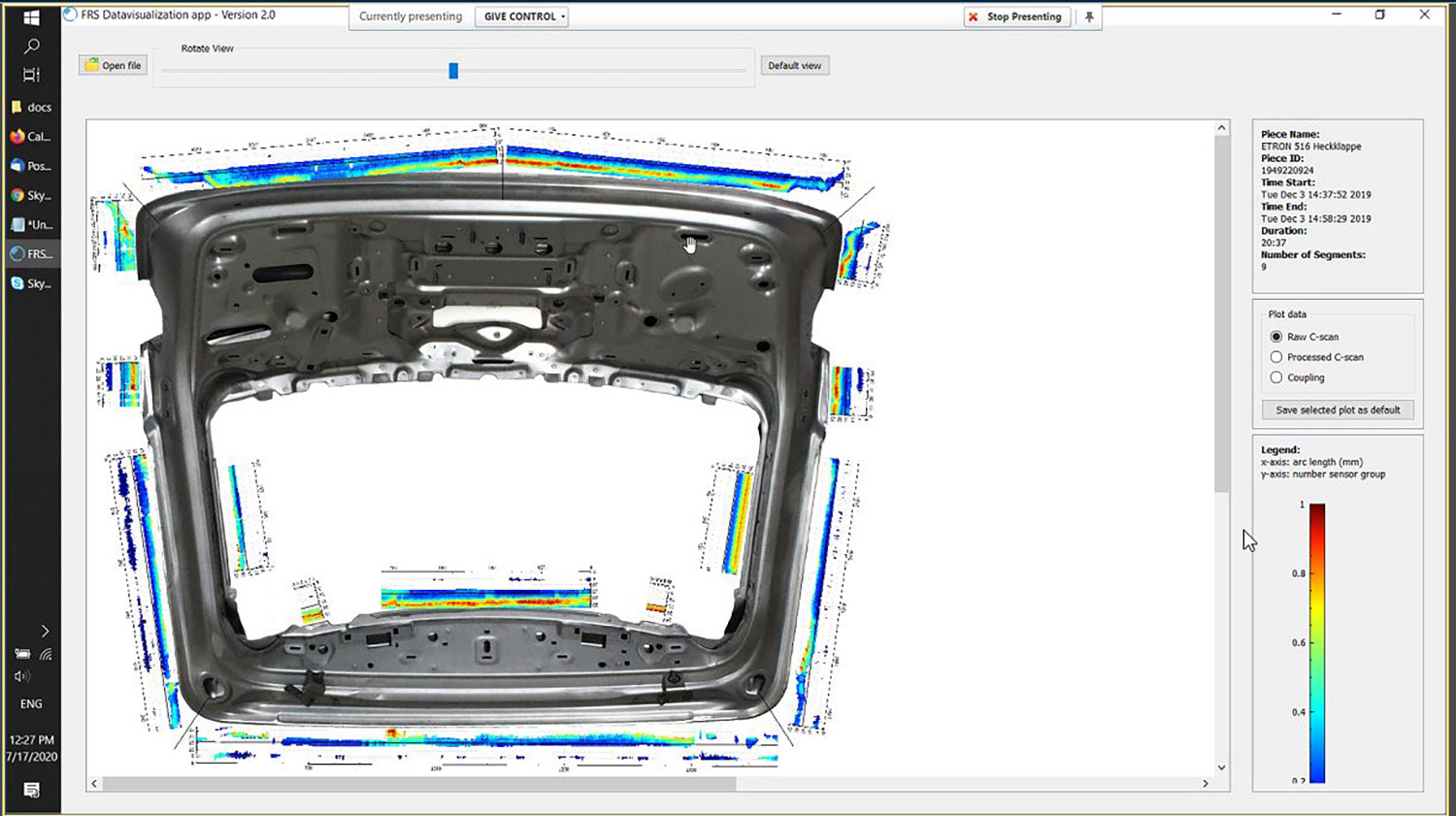

User-friendly operator interface

Adaptive control using ultrasonic signal feedback

Solution Configuration

The URQC-100 solution is tailored to your needs. It consists of the following key components:

• Industrial 6-axis robot equipped with a real-time (250 Hz) Ethernet interface

• Robot controller for driving the industrial robot

• Computer for intelligent robot motion control

• Ultrasonic sensor (conventional or phased array), ultrasonic signal processing and - display module connected to the computer

• Force sensor module

• Coupling liquid dispersion module; I/O modules; part manipulation module

• Peripherals including fence and operator console

Download Product Card

When you are interested, feel free to download the URQC-100 Product Card here.

The two-page Product Card contains a general product and application description along with more detailed information related to product configuration, features and graphical user interface.