Ultrasonic Robotic QC

New Flexible Robot Cell

Operational at Audi Brussels

Key Advantages

'Ultrasonic Robotic QC' drastically reduces or eliminates scrap and decreases related CO2 emissions. Such a robot cell excellently fit into Industry 4.0 automation initiatives supporting higher quality, efficiency and traceability.

Compared to manual inspection, it is like having your best quality control operators on the job and increase productivity at the same time – and make sure they never get tired. The automated adaptive process delivers more robust and flexible ultrasonic quality control, which leads to consistently better produced items. The robot takes over ergonomically burdening tasks from operators, while they can continue work near the robot.

Drastically Reduces or Eliminates Scrap

The quality control is no longer destructive. All parts are tested by a robot in a non-destructive mode.

More Reliable Inspection Results

Robust & reliable ultrasonic inspection of part series – flexibly handling geometric variations in production.

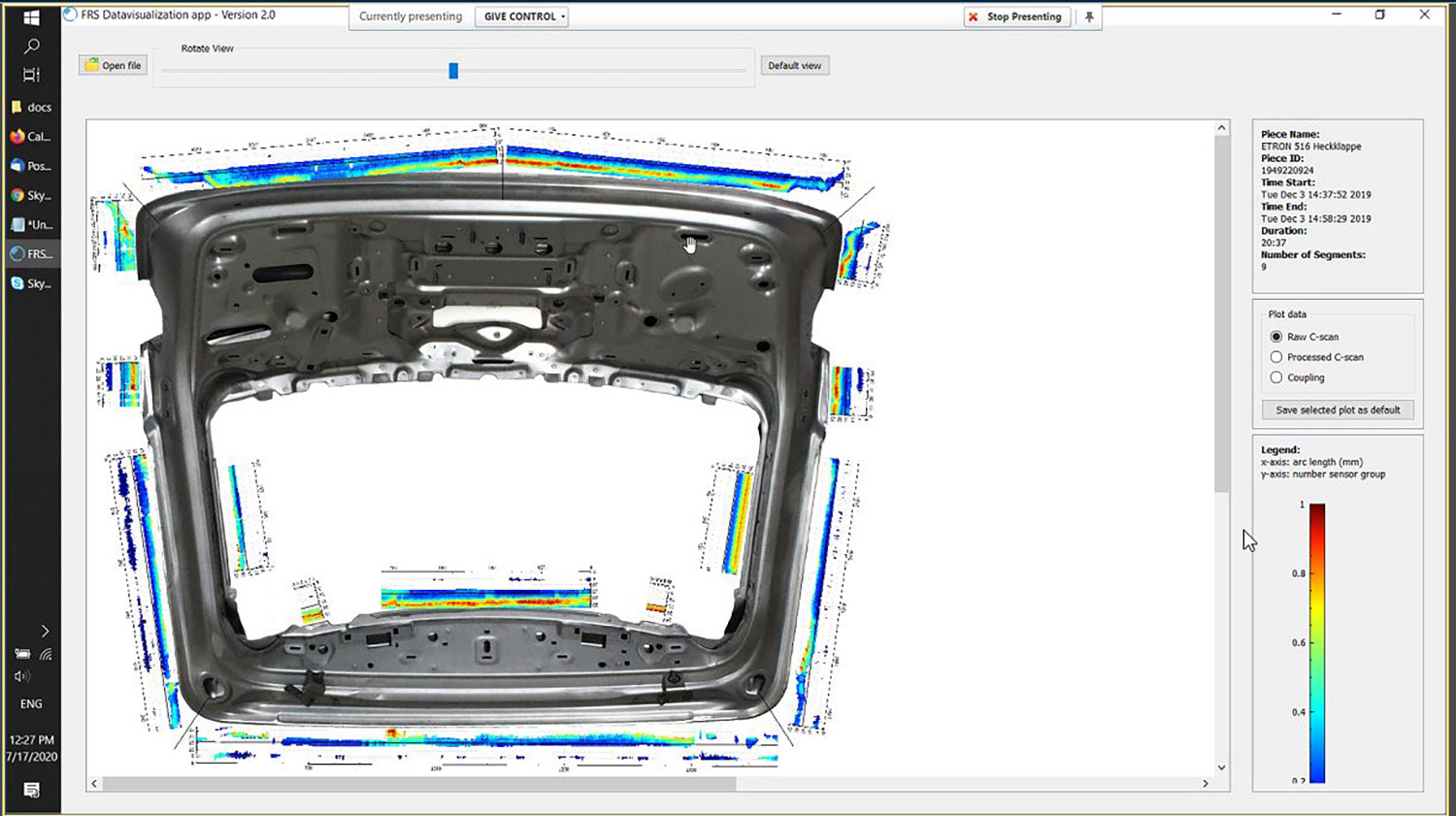

One Cell Can Inspect Multiple Car Parts

Operators easily switch to another car part by selecting the part from a computer screen.

Faster than Experienced Operator

‘Ultrasonic Robotic QC’ speeds up inspections by adaptively guiding the ultrasonic sensor.

Tackling Automation Hurdles

Revolutionizing Ultrasonic Inspection